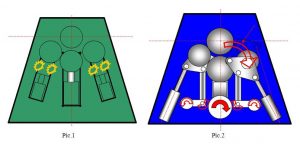

AR- line: Section bending machines aka known as angle rolls with three driving rolls, each with an independent hydraulic planetary motor, two forming rolls for reduction of flat ends. Double roll spherical bearings for maximum rigidity, hydraulic motors attached directly to each planetary drive, eliminating the loss of torque. Winner technology for all section bending types up to 500 HE beams.

AR- line: Section bending machines aka known as angle rolls with three driving rolls, each with an independent hydraulic planetary motor, two forming rolls for reduction of flat ends. Double roll spherical bearings for maximum rigidity, hydraulic motors attached directly to each planetary drive, eliminating the loss of torque. Winner technology for all section bending types up to 500 HE beams.

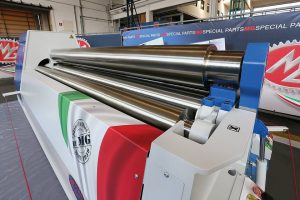

PK Plate Roll Model is simple in its design but strong and reliable. It offers mass production with the minimum maintenance. Completely re-designed in its frame and systems, gets the torsion bars, levers and transmission systems and the opportunity to adapt vacuum conveyor, loading table, supports and ejecting system from the MH plate roll line. Winner technology at the right price.

M 4-roll plate bending rolls: MG has updated the radial movement of their plate rolls resulting in stronger and more efficient side rolls movements rolling even when the machine works at its capacity limit. The hydraulic motors of the two central rolls are coupled to their planetary gear boxes. The gear boxes are mounted directly on the rolls without secondary transmissions, this way there is no lost of power and no need of parts maintenance. Massive torsion bars grant the absolute rolls parallelism. These torsion bars together with all the hydraulic device generate a peculiar system that gives absolute precision and versatility. Winner technology for great performance and safety.

G 3-roll plate bending rolls: Having the same features of M plate roll line, the 3 rolls plate bending rolls range is built with 3 powered rolls; all MG bending rolls are manufactured expressly to customers’ needs. Our range is the largest in the field; from 300mm to 8000mm width, for thickness from 0,2mm up to 200mm cold rolling. Winner technology at customer’s disposal.