Recently, American manufacturing industries have seen dark days as economic decline over the past few decades has claimed more and more good paying jobs every year. The factories and manufacturing lines that made the United States a world power haven’t stopped production entirely, but they’ve slowed considerably. Still, there are signs that America is starting to make a turnaround in this important aspect of our economy.

Recently, American manufacturing industries have seen dark days as economic decline over the past few decades has claimed more and more good paying jobs every year. The factories and manufacturing lines that made the United States a world power haven’t stopped production entirely, but they’ve slowed considerably. Still, there are signs that America is starting to make a turnaround in this important aspect of our economy.

The strongest gains have been felt in the housing and automobile industries, which is great news for those two markets as both have been maligned in recent years. According to this piece from Bloomberg.com car manufacturers are producing vehicles at their fastest rate in six years. The factory output for American-made furniture and appliances has also eclipsed its previous highest level, set in 2009.

These increased production levels have led to a need for additional workers for many top employers around the country. For instance, one Ford plant in Flat Rock, MI, may see a hiring explosion of 1,400 new employees as the corporation debates whether to increase production of its Fusion vehicle line. Overall, auto manufacturing assembly plants produced an annualized rate of 11.25 million units produced during the month of August, the fastest pace since June 2007.

Not only are manufacturing firms healthy now, but a backlog of unfilled orders promises to keep many companies in business through the coming years. For other industries, even minor gains are signs of improvement for the future. Domestic production of computer and electronics increased by 1.6 percent over the past year, while construction materials also increased in output by 0.3 percent.

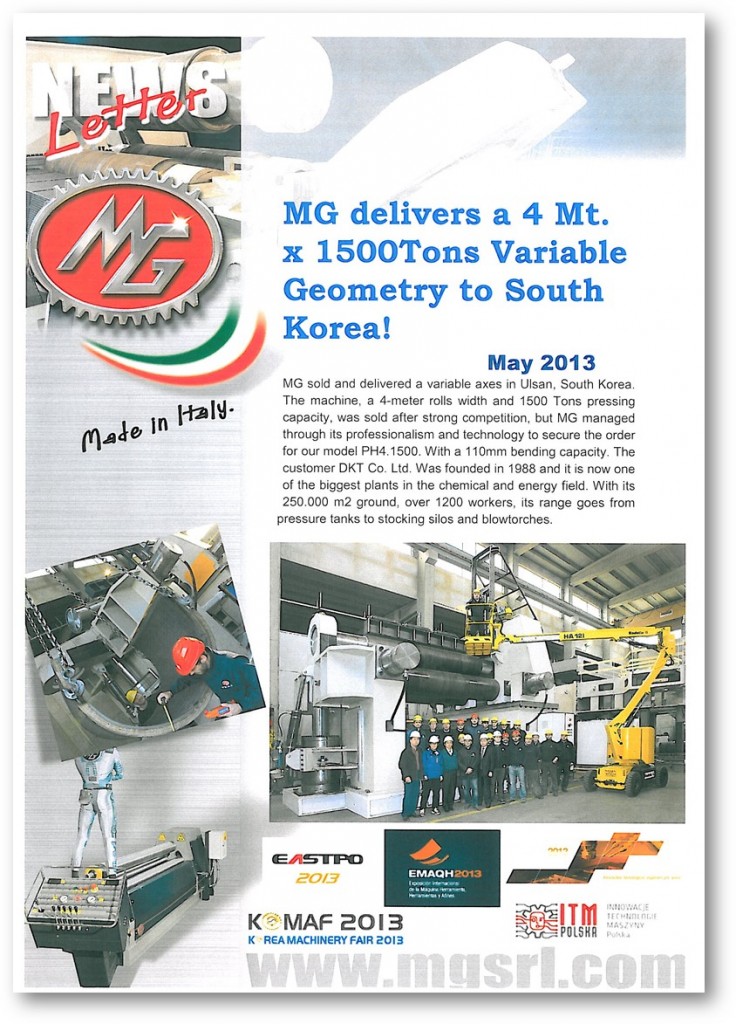

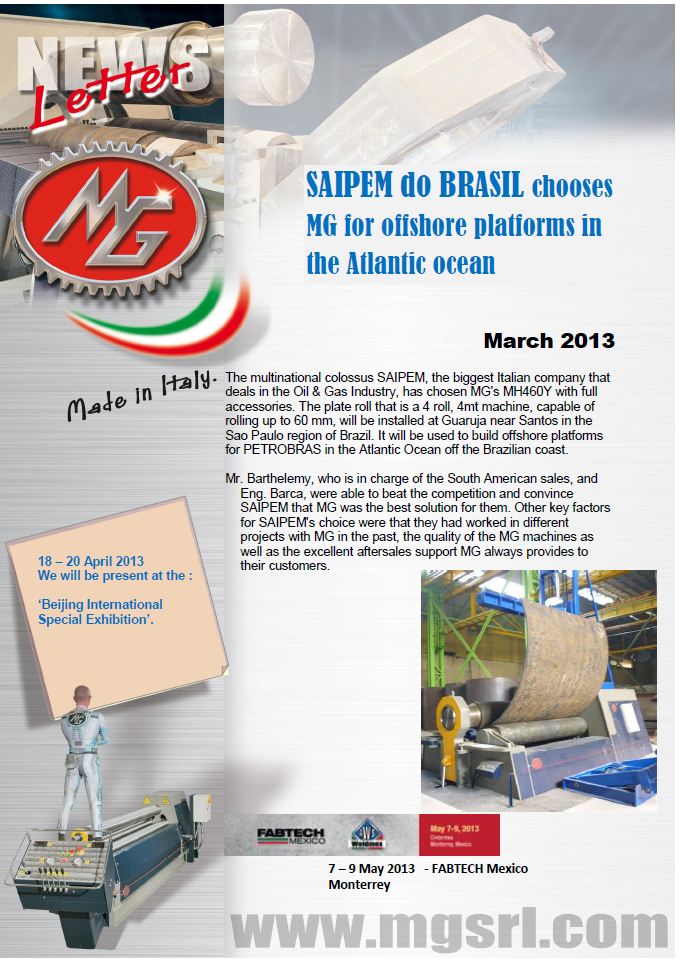

In order to keep manufacturing operations in line, a corporation needs to make sure that they have the right fabrication machinery on hand. Marshall Fabrication Machinery is proud to offer a long line of products that can aid a wide variety of manufacturing goals. From plate roll machines to press brakes and shears, our equipment can be implemented in various assembly situations. We also provide high quality rebar benders and cutters for construction applications.

*Image courtesy of Andrey Shadrin