CLINK LINKS/PICTURES BELOW FOR INFORMATION

CLINK LINKS/PICTURES BELOW FOR INFORMATION

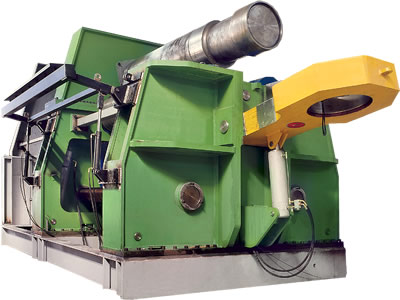

The most economical and powerful machine among the 3-rolls mechanical plate bending machines. Because of the electrical motor on the upper and lower rolls, driven by planetary gearbox through a gear system this machine is the most preferable type in the sheet metal processing industry.

The most economical and powerful machine among the 3-rolls mechanical plate bending machines. Because of the electrical motor on the upper and lower rolls, driven by planetary gearbox through a gear system this machine is the most preferable type in the sheet metal processing industry.

The machine is built of St-52 steel, is robust and long-lasting by the welded steel frame.

Click HERE for specifications

Mobdro is one of the best media players that enable you to stream unlimited TV channels, latest videos, and movies, daily TV shows, etc. for free without paying a penny. So in Mobdro for iPad, there’s no chance of missing your favorite TV shows due to inconvenient of times. You can easily download this application from your App Store for free, and once you download it, you can enjoy your favorite shows at anywhere anytime.

So if you are an iPad user, download the Mobdro application right now and enjoy every entertainment for free. You can also watch Hollywood music videos and movies without any restrictions.

Checkout below the coolest features of Mobdro application for iPad devices.

It is very easy to download and installed Mobdro for iPad devices because the application is available on the biggest platforms of App Store. So follow the instructions carefully that is given below:

You can also go for alternative Apps like Mobdro for PC incase of any complications in the apps. Check out the alternatives given below:

Conclusions:

So, this way you can easily download Mobdro applications in your iPad devices and enjoy exploring all the entertainments for free absolutely. Also in the case of any problems and complications in the app, you can also opt for the free alternatives options that are given above.

CLICK LINKS/PICTURES BELOW FOR MORE INFORMATION

CNC-AP SPEED-BEND Synchronized Hydraulic Press Brake

Heavy-Duty Special Design Press Brake

Frames made out of welded steel and worked on CNC milling-boring machines.

MG owns a new geometry bending system characterized by radial movements off the bending rolls and movements totally assembled on high load dynamic bearings that grant a minimum friction and a smooth rolling even when the machine works at its capacity limit. The bearings supporting the rolls are mounted in watertight compartments with grease, protected from the external dust and pollution and having permanent lubrication.

The hydraulic motors of the two central rolls are coupled to their epicycloidal gear boxes.

The gear boxes are mounted directly on the rolls without secondary transmissions; this way there is no loss of power and no need of parts maintenance. Massive torsion bars grant

the absolute parallelism. These torsion bars, together with all the hydraulic device, generate a system that gives absolute precision and versatility.

Whether you are a job shop or manufacturer, the MG 4 Roll is the best plate roll solution. Every machine, size for size, can roll 30% tighter diameters than any type roll and 30% thinner material than 3 roll double pinch machines. These features, combined with the advanced technology incorporated in all aspects of the MG Plate Roll, make it up to 300% more efficient than 3 roll machines. The following graphs explain why.

Planetary drive eliminates complicated transmission systems which are not energy efficient. Delivers in excess of 98 % of all created energy to roll surface. Also eliminates the need for clutches and complicated synchronization devices.

Unlike electronic systems or proportional value systems, which maintain a theoretical balance, the MG Plate Roll maintains a mechanical finite parallelism through our exclusive torsion bar system which allows the machine to be adjusted to its full conical tilt and back to parallel in only 5 seconds for the life of the machine.

By using exclusive planetary guides, available on MG Plate Rolls, we are able to keep approximately 50% more area of the plate under bend pressure during the rolling operation, thereby allowing the MG Plate Rolls to roll down to 1.1 the upper roll diameter. This allows MG Rolls to have a 30% advantage on tight diameters.

Spherical roller bearings are extremely energy efficient. The eliminate bushings and the necessary running tolerance they require. A negligible loss of energy due to friction whereas bronze bushings take 25-30% of available energy to overcome inherent friction.

Lubricated for life.

Lubricated for life.

Through exclusive technology, MG Plate Rolls can develop cones as easily as competitive machines can develop cylinders. And it eliminates scarring on the surface of shell or roll and also eliminates, in most cases, the need for grinding the lamination (bullnosing) on the minor diameter edge.

When choosing a 4-roll machine with a CNC control, there is no better choice than the Touch Command EVO.

Click HERE for detailed information on the CNC Touch Command EVO.

Video below showing model MH

Driven by electric motor, planetary gearbox and gear system

Driven by electric motor, planetary gearbox and gear systemSpecifications will be available shortly.

Driven by electric motor, planetary gearbox and gear system

Driven by electric motor, planetary gearbox and gear systemSpecifications will be available shortly.

Machine body manufactured of st-52 special steel

Machine body manufactured of st-52 special steel

Model #: AR140, 5 X 5 X 1/2″ angle leg out

Using the same award-winning technology incorporated in MG’s world-famous 3 and 4 roll plate bending machines, MG has revolutionized the section and angle rolling market. Using the same characteristics and components as MG’s plate bending machines, MG is able to offer stronger machines with higher quality and performance than other manufactures to a very competitive price.

AR140, 5 X 5 X 1/2″ angle leg out

Profile Bending Machines Ready to Use

Standard equipment includes a set of modular rolls that are suitable for rolling most of the commonly used commercial sections such as flats, angles, square and rectangular tubes, Tees, channels, and beams.

The three-dimensional lateral guide rolls are hydraulically powered on the AR140 and larger machines and can be adjusted to work very closely to the bending rolls, minimizing the distortion of non-symmetrical profiles. Moreover the guide rolls are equipped with the tooling to bend angle leg-in. This tooling can also be effectively used for calibrating the bending diameters or recovering bends that are too tight.

AR360, 8 X 8 X 1-1/8″ leg in and out

Machines with controlled axis are required to achieve consistent curves between straight parts, multiple radii or compound curves, tapered or variable pitch helical coils, pancake coils, etc.

The AR line offers two types of controls which allow you to store your programs.

The MG 3000 Control electronically interfaces with all three axis. The feeding speed is infinitely variable.

In addition to electronically interfacing with all three axis, the CNC PRO Control has the capability to interpolate the movements of the forming rolls with any other axis. The Control has data connection capability. It can be linked with other PC via floppy disk, serial port or LAN. The feeding speed is also infinitely variable.

|

Traction and Compression tooling used for IPE – NP – HE – UNP the hard way.

|

|

AR 140 |

Central support for big diameters or spirals. Frontal and powered support for spirals up to 6 meters long . |

|

Radius measuring tool

|

|

|

Remote control

|

| Model | Angle | Speed | Motor power | Shaft | Roll diameter | Weight | Length | Width | Height |

| Inch | IPM | HP | Inch | Inch | Lbs | Inch | Inch | Inch | |

| AR60M | 2×1/4 | 237 | 4 | 2.4 | 8.5 | 2,026 | 54 | 38 | 54 |

| AR60 | 3×1/4 | 237 | 4 | 2.4 | 8.5 | 2,026 | 54 | 38 | 54 |

| AR80M | 3×3/8 | 237 | 5.5 | 3.2 | 10.4 | 3,630 | 54 | 46 | 54 |

| AR80 | 3×3/8 | 237 | 5.5 | 3.2 | 10.4 | 3,630 | 54 | 46 | 54 |

| AR110 | 4×1/2 | 237 | 10 | 4.3 | 13.8 | 6,498 | 62 | 39 | 62 |

| AR140 | 5×1/2 | 237 | 15 | 5.5 | 15.8 | 8,810 | 73 | 65 | 73 |

| AR160 | 6×1/2 | 237 | 25 | 6.3 | 19.1 | 14,980 | 83 | 77 | 83 |

| AR180 | 7×11/16 | 237 | 30 | 7.5 | 22.8 | 29,075 | 90 | 103 | 9 |

| AR200 | 8×3/4 | 237 | 40 | 8.3 | 25.6 | 52,800 | 110 | 116 | 110 |

| AR250 | 8×3/4 | 237 | 60 | 9.8 | 26.8 | 63,800 | 118 | 117 | 118 |

| AR300 | 8×1 | 237 | 76 | 11.8 | 31.5 | 80,470 | 125 | 138 | 125 |

| AR360 | 8×1-1/8 | 237 | 102 | 14.2 | 31.5 | 132,280 | 176 | 191 | 136 |

Below a video on model AR profile bending rolls