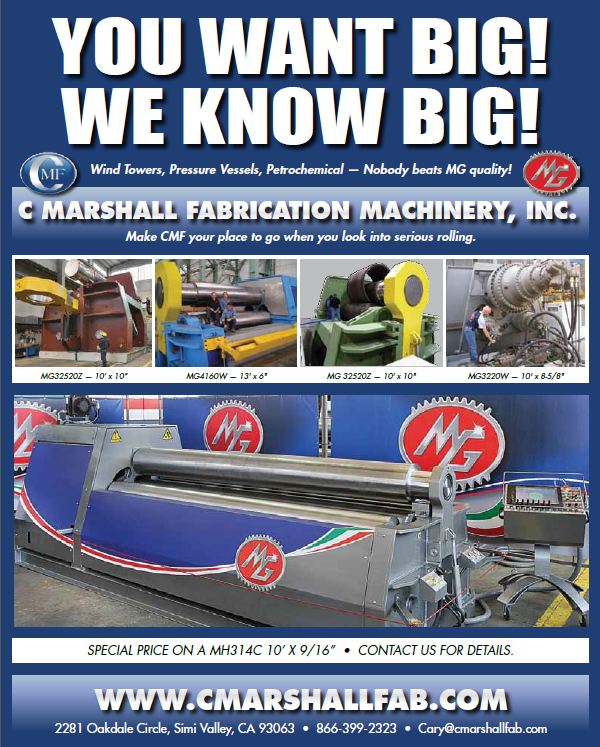

Pictures of the MG 3 roll plate roll – model G3075Y – recently purchased by a company located on the US west coast. Photos taken during set-up.

Technical data

Installed power: 100 HP

Top roll diameter: 26.8″ (680 mm)

Side rolls diameter: 20.9″ (530 mm)

Capacity

Working length: 122″ (3100 mm)

Max. rolling thickness: 3″ (75 mm)

Max. pre-bend thickness: 2-3/16″ (55 mm)

Size (approx.)

Width: 109″ (2750 mm)

Total length: 272″ (6900 mm)

Height: 141″ (3560 mm)

Working height: 95.3″ (2420 mm)

Weight: 110,000 lbs. (50 metric tons)