Manufacturers in the U.S. have a more optimistic outlook for sales and spending in 2011 than they did at the end of last year, according to a survey by the Institute for Supply Management.

Purchasing managers at U.S. factories anticipate sales will grow 7.5 percent this year, up from a 5.6 percent December forecast, according to the Tempe, Arizona-based group’s semiannual forecast issued today. By contrast, service providers estimated revenue will rise 2.1 percent this year, less than the 3.4 percent forecast in December.

“Much of manufacturing has emerged from the economic downturn and is experiencing significant growth,” Norbert Ore, chairman of the group’s factory committee, said in a statement.“The positive forecast for revenue growth and improved employment will drive the continuation of the recovery” in the industry, he said.

Companies like Corning Inc. (GLW) may continue to profit from growing emerging economies as well as increased capital investment, keeping manufacturing at the head of the economic rebound. Growth among service providers, which by the ISM’s accounting make up more than 90 percent of the economy, may fail to keep pace as American households struggle with 9 percent unemployment.

Manufacturers projected employment will increase 2.9 percent for the rest of this year, while service companies predicted a 0.9 percent increase.

More Investment

Factory managers also estimated they will boost spending on new equipment by 18 percent in 2011, up from the 14.5 percent increase projected in December, today’s report showed. Service providers forecast a 1.4 percent gain in investment, less than the 3.7 percent gain predicted at the end of last year.

“Indications are that non-manufacturing will continue on the path of slow and sustainable growth for the balance of 2011,” Anthony Nieves, chairman of the ISM’s services committee, said in a statement. “Price increases and slow employment growth are prominent areas of concern.”

A report today showed manufacturing cooled last month, reflecting a drop in auto making after supplies of parts were disrupted by the Japanese earthquake and tsunami.

Production Disruption

Output at factories, mines and utilities was unchanged after a 0.7 percent gain in March, figures from the Federal Reserve showed. Manufacturing fell 0.4 percent, led by an 8.9 percent slump in production of automobiles and parts.

In response to a special question, 23 percent of manufacturers surveyed by ISM said they will experience delays in U.S. operations due to supply shortages caused by the disaster in Japan. Fifteen percent of those in services projected disruptions.

Factory leaders see the cost of raw-materials rising 7.4 percent this year and believe they can pass along 34 percent of that increase to customers, the report showed. Service providers see a 4.7 increase in input costs this year, with 27 percent of the gain being passed through.

Earlier this month, the ISM reports showed manufacturing expanded faster than expected in April, driven by gains in exports and inventories. At the same time, service industries grew at the slowest pace in eight months as companies cut back in response to higher energy costs.

ISM Gauges

The ISM’s factory index fell to 60.4 in April from 61.2 the prior month, figures showed May 2. The measure has exceeded 60 for four consecutive months, the best performance since 2004. For both indexes, readings greater than 50 signal growth.

Corning, which makes glass for flat-panel televisions, said it expects sales will grow to $10 billion by 2014, helped by demand from China.

“We’re off to a great start in 2011,” Wendell Weeks, chairman and chief executive officer, said in a statement after the Corning, New York-based company’s annual meeting last month. A significant portion of growth will come from China, which is currently the world’s largest market for several of Corning’s major products, he said.

Two days after the factory gauge was released, the ISM reported that its index of non-manufacturing companies declined to 52.8 in April, lower than the median forecast of economists surveyed by Bloomberg News, from 57.3 in March.

Climbing gas prices have strained earnings at service providers like Union Pacific Corp. (UNP), the biggest U.S. railroad by sales, which posted a quarterly profit on April 20 that trailed analysts’ estimates.

Omaha, Nebraska-based Union Pacific utilized commodity-shipping volume growth “despite spiking fuel prices and winter weather challenges across most of the nation’s rail network,”Chief Executive Officer Jim Young said in a statement.

By Alex Kowalski – May 17, 2011 8:12 AM PT

To contact the reporter on this story: Alex Kowalski in Washington at akowalski13@bloomberg.net

To contact the editor responsible for this story: Christopher Wellisz at cwellisz@bloomberg.net

It must be something in the cyberspace ether, but two weeks after I wrote my last blog article on “Magnetic Boy”, our not-so-little friend from Croatia seems to be creating a new internet sensation. Thanks perhaps to the fact the he’s now a few years older and his body mass has increased as well, to disproportionately high levels in fact, “Magnetic Boy”is now said to be able to get up to 25 kilos of metal to stick to him at any given time. Do a quick Google search and in short order you will find an epic recent photo of him wearing a household iron on his bare chest, which I can only hope wasn’t on at the time. I bet he’s really good at finding the car keys as well.

It must be something in the cyberspace ether, but two weeks after I wrote my last blog article on “Magnetic Boy”, our not-so-little friend from Croatia seems to be creating a new internet sensation. Thanks perhaps to the fact the he’s now a few years older and his body mass has increased as well, to disproportionately high levels in fact, “Magnetic Boy”is now said to be able to get up to 25 kilos of metal to stick to him at any given time. Do a quick Google search and in short order you will find an epic recent photo of him wearing a household iron on his bare chest, which I can only hope wasn’t on at the time. I bet he’s really good at finding the car keys as well. Not a well-known fact but nonetheless a true one: the car industry recycles more materials than any other industry on the planet. This is because metal is an excellent resource to recycle, and extremely cost-effective to do so as well. If it didn’t make sense financially to recycle all the metal in old cars, the auto industry wouldn’t be doing it.

Not a well-known fact but nonetheless a true one: the car industry recycles more materials than any other industry on the planet. This is because metal is an excellent resource to recycle, and extremely cost-effective to do so as well. If it didn’t make sense financially to recycle all the metal in old cars, the auto industry wouldn’t be doing it.

Once again this week, I threw myself wholeheartedly into a Google search for the largest metal object in the world, if only because I know that my scores of avid followers on this blog have all been holding their breath since I brought this subject up in last week’s blog entry. And once again this week, I got completely sidetracked. You would have too, after scanning the Google results for “large metal object”.

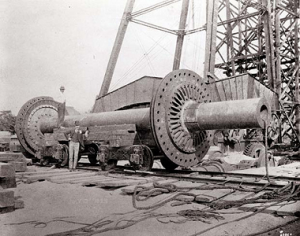

Once again this week, I threw myself wholeheartedly into a Google search for the largest metal object in the world, if only because I know that my scores of avid followers on this blog have all been holding their breath since I brought this subject up in last week’s blog entry. And once again this week, I got completely sidetracked. You would have too, after scanning the Google results for “large metal object”. I’ve been curious for some time to find out what the largest metal object in the world is. By “largest metal object in the world”, I mean an object that is formed out of solid metal and is one contiguous piece of homogeneous metal. In other words, search results that yielded things like “largest metal sculpture in the world” don’t count, in my opinion. Additionally, I was looking for something that served an actual purpose, not just something to look at.

I’ve been curious for some time to find out what the largest metal object in the world is. By “largest metal object in the world”, I mean an object that is formed out of solid metal and is one contiguous piece of homogeneous metal. In other words, search results that yielded things like “largest metal sculpture in the world” don’t count, in my opinion. Additionally, I was looking for something that served an actual purpose, not just something to look at.