Manufacturing in the U.S. expanded more than forecast in January, reaching a nine-month high and showing the industry is starting to improve.

The Institute for Supply Management’s manufacturing index climbed to 53.1 last month from December’s 50.2, the Tempe, Arizona-based group’s report showed today. Readings above 50 signal expansion. The figure exceeded the highest estimate in a Bloomberg survey of 86 economists. The median forecast was 50.7.

Stocks extended gains after the report showed gains in orders, production and factory employment after a fourth-quarter acceleration in consumer purchases and a rebound in business spending. The housing recovery and stabilization in overseas markets indicate factories may keep adding to growth in the world’s largest economy this year.

“Manufacturing is on the mend,” said Brian Jones, senior U.S. economist at Societe Generale in New York, who projected a reading of 52. “Things are getting better as we begin the year.”

The Standard & Poor’s 500 Index climbed 0.8 percent to 1,509.7 at 10:47 a.m. in New York.

Another report this morning showed hiring increased in January after accelerating more than previously estimated at the end of 2012, evidence the U.S. labor market was making progress even as lawmakers quarreled over the federal budget.

Payrolls rose 157,000 following a revised 196,000 advance in the prior month and a 247,000 surge in November, Labor Department figures showed today in Washington. The revisions added a total of 127,000 jobs to the employment count in November and December. The jobless rate increased to 7.9 percent from 7.8 percent.

Economists’ Estimates

Estimates for the January ISM gauge in the Bloomberg survey ranged from 49.2 to 52.5.

“While we’re off to a great start” to the year, “we just have to see how things materialize,” Bradley Holcomb, chairman of the ISM factory survey, said on a conference call with reporters. “We’re not out of the woods yet.”

Today’s report showed the ISM’s production index increased to 53.6 from 52.6. The new orders measure rose to 53.3, the highest since May, from 49.7.

The employment gauge increased to seven-month high of 54 from 51.9 in the prior month.

The measure of orders waiting to be filled fell to 47.5 from 48.5. The inventory index climbed to 51 from 43. A figure higher than 50 means manufacturers are building stockpiles. A gauge of customer stockpiles rose to 48.5 from 47.

Prices Paid

The index of prices paid increased to 56.5 from 55.5.

Manufacturing, which accounts for about 12 percent of the U.S. economy, was at the forefront in the early stages of the recovery that began in June 2009.

Figures yesterday showed the MNI Chicago Report’s business barometer rose to 55.6 in January, the highest since April, after 50 in December, signaling business activity picked up.

Elsewhere, U.K. manufacturing expanded in January for a second month. A gauge of factory activity eased to 50.8 from a revised 51.2 in December, Markit and the Chartered Institute of Purchasing and Supply said in London today.

In the euro-area, manufacturing continued to shrink. Markit’s gauge rose to 47.9 last month from 46.1 in December.

Chinese Manufacturing

Chinese manufacturing expanded in January, validating the nation’s reluctance to add to policy stimulus amid increasing inflation concern.

The Purchasing Managers’ Index was 50.4 in January compared with 50.6 in December, the National Bureau of Statistics and China Federation of Logistics and Purchasing said today in Beijing as they more than tripled the number of companies surveyed. A separate gauge from HSBC Holdings Plc and Markit Economics covering fewer businesses rose to a two-year high of 52.3 from 51.5.

Earlier this week, a Commerce Department report showed business investment in equipment and software climbed at a 12.4 percent annual rate in the fourth quarter, the best performance in more than a year, after a drop the prior quarter.

Caterpillar Inc. (CAT), the world’s largest maker of construction and mining equipment, is among manufacturers expecting an improving outlook.

‘Increasingly Optimistic’

“In the United States, we’re becoming increasingly optimistic,” Michael DeWalt, a spokesman for Peoria, Illinois- based Caterpillar, said on a Jan 28 conference call with analysts. “We expect U.S. housing industry to help the economy in 2013.”

An improving housing market is also helping manufacturers such as DuPont Co. (DD), the biggest U.S. chemical maker by market value. Rising demand for plastics used in autos helped the Wilmington, Delaware-based company to report fourth-quarter earnings that exceeded analysts’ estimates. DuPont also said sales in 2013 will climb to $36 billion from $34.8 billion.

“The U.S. is experiencing a weak recovery with bright spots and pent-up demand for housing and autos,” Chief Executive Officer Ellen Kullman said on a Jan. 22 earnings call.

Consumer purchases grew at a 2.2 percent pace in the fourth quarter, up from 1.6 percent in the previous three months, as Americans bought more durable goods including automobiles. A plunge in defense outlays and slower stockpiling led the economy to contract at a 0.1 percent annual pace in the final three months of 2012.

Automobile purchases also may support factory production this year. November-December was the best back-to-back showing for car- and light-truck sales since early 2008, according to Ward’s Automotive Group.

To contact the reporter on this story: Shobhana Chandra in Washington atschandra1@bloomberg.net

To contact the editor responsible for this story: Christopher Wellisz at cwellisz@bloomberg.net

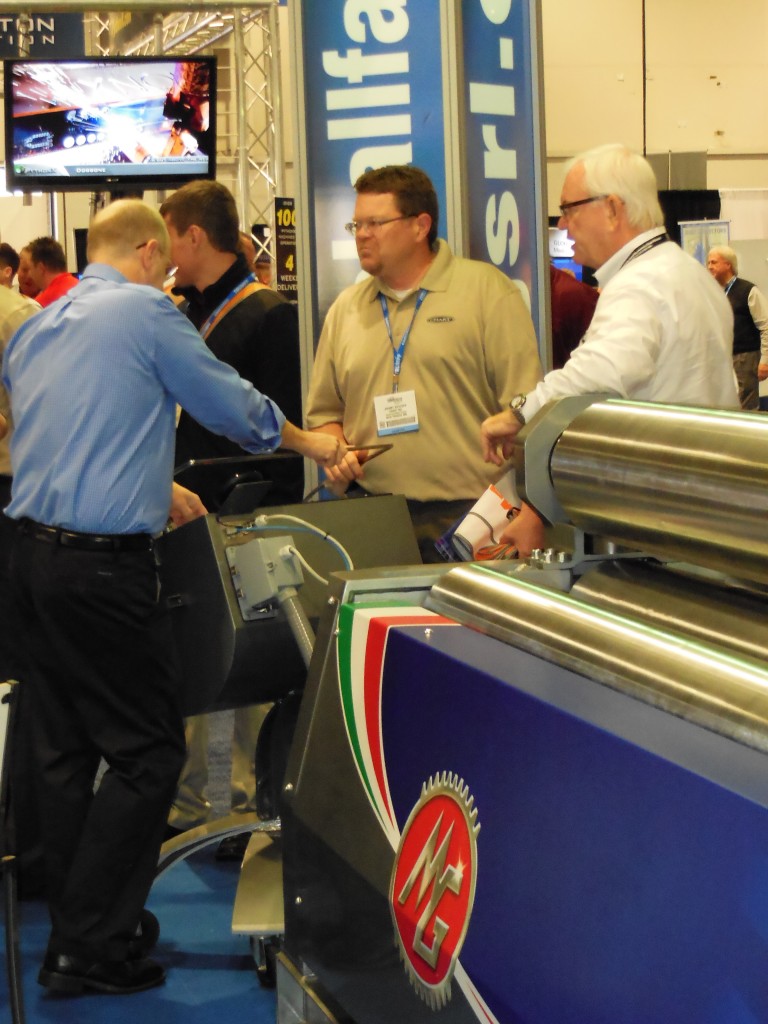

We generated more quality leads in Las Vegas than in the last year’s Fabtech Show in Chicago show where the quantity of leads ended up surpassing the quality. This year in Las Vegas we did not have many “tire-kickers” visit our booth but customers that were seriously looking to purchase machines. Discussions were lively and productive.

We generated more quality leads in Las Vegas than in the last year’s Fabtech Show in Chicago show where the quantity of leads ended up surpassing the quality. This year in Las Vegas we did not have many “tire-kickers” visit our booth but customers that were seriously looking to purchase machines. Discussions were lively and productive.