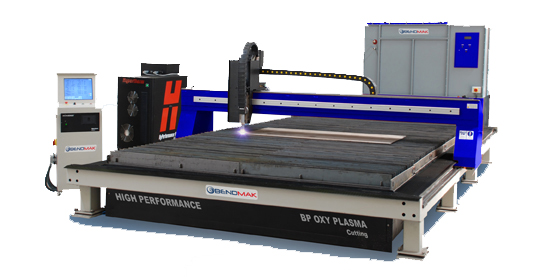

Cutting with profit. Less scrap, more automation, higher performance.

Cutting with profit. Less scrap, more automation, higher performance.

Standard Features

- Solid steel construction designed for high speeds

- Fume extraction table with pneumatic switch control, exchangeable grills, dross collecting system which allows clean, safety and healthy working environment by vacuuming dust and fume which raises during plasma cutting process

- High precise positioning possibility with linear sledge system in all axis

- Synchronized drive allows a smoothly and vibration free motion

- Brushless AC servo motors ( on all axis)

- Pinion and gear rack drive system facilitates smooth and fast motion

- Up to +.004” precise positioning

- Automatic height control and automatic ignition torch system

- Torch collision protection

- Windows based CNC control unit

- Vestige plate stock management database with optional auto-nesting program which provides economy on material and saves time

- In comparison to laser cutting, plasma cutting decreases the cost of the process by 20%. With similar cutting quality, plasma is a preferable alternate to laser cutting.

- Cutting surface is close to 90 degrees and the vertical roughness tolerance is in minimum level.

- Manual

HYPERTHERM EDGE UNIT (USA)

- Graphical user interface, easy and flexible use with SOFTMOTION technology

- Windows based industrial PC

- Touch screen display

- Strong and reliable processor

- 15” LCD Monitor (touchscreen)

- Standard PC power supply

- Automatic and manual control during oxy-cutting process

- USB, CD, floppy disc input to load the shapes

- Cutting processes are can be followed from the screen

HYPERTHERM 130

- Cutting mild steel from .020” to 1.5”

- Prevents dross by cutting, so no second cutting process required

- Easy, fast and correct gas usage through optional auto gas control.

- Saves cost by high definition cutting quality.

- Depending on material no or only little dross formation

- Durable torch consumables

- Minimum gas and energy loss through high definition plasma arc technology

- Repeatable cutting quality

- Perfect cutting quality of Hy-performance on stainless steel

- Durable consumables

- Hy-performance plasma control is user friendly.

- Changing of the torch very easy and fast

- Bevel cutting possibility up to 45 degrees.

- Marking is also achievable with the same torch. With the continuously

current gauge the cutting performance could be repeated up to 1-9/16”.

HYPERTHERM Command THC

Height control

- Torch height control can be adjusted easily by arc voltage feedback control which affects the cutting quality positively.

- Collision avoidance system is designed mechanically and electronically.

- Torch height control system through microprocessor.

- All values and also errors could be found easily through the relaying indicators.

- Optional breakdown is designed in order to reduce or eliminate damage to the torch due to accidental collisions in all axis.

- System control can be reviewed or can be transferred to the CNC control.