Category: Blog

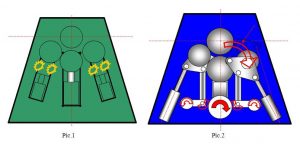

Comparing 4 rolls vs. 3 rolls. What are the advantages and disadvantages?

Four-roll technology has been around almost since the turn of the century: however, it was impractical, as the improved production did not justify the costs.

Four-roll technology has been around almost since the turn of the century: however, it was impractical, as the improved production did not justify the costs.

With the advances in Fluid Technology this has changed dramatically. It is now possible to buy a four-roll machine for very nearly the cost of a three-roll double pinch machine.

Is this an important development to plate roll users? To answer this question, let’s briefly review the functions of the single initial pinch roll, double pinch roll and the basic pyramid roll.

Click HERE to read the entire article.

FABTECH 2016 Returns to Las Vegas – November 16-18, 2016

…and we are excited to be part of this great show and hope that you will stop by at our booth C26103 to learn more about us and our MG plate and angle roll line.

Come talk to our knowledgeable and friendly sales personnel. Ask questions. Pick up brochures. Get ideas.

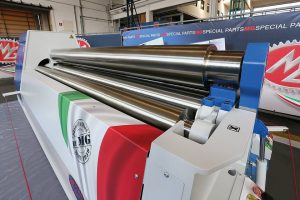

We are proud to showcase a M3015C Double Pinch Hydraulic 4-roll Plate Bending Machine (10′ x 19/32″) with a CNC Touch Command EVO control. Click HERE for information on M3015C. See pictures below of the actual machine.

The factory, MG, that builds our rolls, was founded in Fossano, Italy in 1959 specializing in industrial automation. Today MG, led by a second generation, relies on a young and dynamic workforce capable of keeping up with the changing global environment. Thanks to a continuous product research and development and to the use of top quality components and most advanced solutions MG can offer a wide range of products that can meet the all the market needs. MG is the market leader in Italy, Germany and Spain with a strong expansion in the developing economies. It is increasing its leadership in North American and Asian continents. With an average production of over 300 machines a year and thanks to a detailed quality control procedure MG can guarantee fast delivery and a high performance product. All the components are top-quality; only the best and most renowned Italian brands are used. Thus MG can guarantee that its products are 100% made in Italy. Thanks to a large stock of spare parts MG can ensure quick deliveries

FABTECH brings a wealth of innovation and technology solutions to Las Vegas, NV November 16-18, 2016. More than 28,000 attendees and over 1,300 exhibiting companies are expected to gather once again to celebrate metal manufacturing at its best. The event also provides educational sessions and expert-led presentations covering the latest trends and technology in the metal forming, fabricating, welding and finishing industries.

COST TO ATTEND

Admission to the show floor is complimentary if you register by the deadline (November 11, 2016). After the deadline and on-site the fee is $50 (US).

2016 SHOW DATES & HOURS

Wednesday, Nov. 16…… 10:00 AM – 6:00 PM

Thursday, Nov. 17……….9:00 AM – 5:00 PM

Friday, Nov. 18…………..9:00 AM – 4:00 PM

LOCATION

Las Vegas Convention Center

3150 Paradise Rd

Las Vegas, NV 89109

Click the button below to register:

Setting up G3075Y – a MG 3 Roll Plate Bending Machine

Pictures of the MG 3 roll plate roll – model G3075Y – recently purchased by a company located on the US west coast. Photos taken during set-up.

Technical data

Installed power: 100 HP

Top roll diameter: 26.8″ (680 mm)

Side rolls diameter: 20.9″ (530 mm)

Capacity

Working length: 122″ (3100 mm)

Max. rolling thickness: 3″ (75 mm)

Max. pre-bend thickness: 2-3/16″ (55 mm)

Size (approx.)

Width: 109″ (2750 mm)

Total length: 272″ (6900 mm)

Height: 141″ (3560 mm)

Working height: 95.3″ (2420 mm)

Weight: 110,000 lbs. (50 metric tons)

American manufacturing isn’t dead yet

Here’s one stat people often cite when talking about the state of U.S. manufacturing: The sector has lost 5 million jobs since 2000.

But there’s another that’s not as well-known: The sector has actually gained about 838,000 jobs since 2010.

To be sure, American manufacturing is no longer the powerhouse it once was. Years ago, it was a stable pathway into a middle class life for blue-collar workers with a high school degree. It’s since lost jobs due to globalization and new technology.

However, that doesn’t mean the industry is on life support.

Auto sales are strong, leading more firms to manufacture cars and car parts domestically. Clean energy companies are building solar panels and wind turbines here. And the space industry is assembling rocket engines and other parts along the Florida coast and elsewhere.

“A lot of challenges remain, but manufacturing is certainly doing a lot better than it was in most of the 2000s and in the Great Recession,” said Scott Paul, president of the Alliance for American Manufacturing, an advocacy and research group.

Related: $75 a day vs. $75,000 a year: How we lost jobs to Mexico

The jobs are out there and many pay well, industry insiders say. In fact, some employers say they are having a hard time filling positions.

Take Craig Technologies, which owns a 161,000 square-foot machine shop in Cape Canaveral, Florida. Carol Craig, who founded the engineering and technology company in 1999, expanded into manufacturing three years ago because she saw the unmet need.

The manufacturing arm, Craig Technologies Aerospace Solutions, builds and repairs complex mechanical and electronic hardware for NASA and the Department of Defense, as well as satellite manufacturers and the commercial aerospace industry. For instance, workers makerocket parts for NASA and its contractors, such as Boeing and Lockheed Martin, as well as satellite parts for companies such as Space Systems Loral and Harris Corporation.

It employs 50 skilled workers and Craig wants to triple the payroll over the next two years. Entry-level positions pay about $40,000, while experienced employees can make double that, she said.

“Manufacturing is on its way back,” said Craig. “The question is how do we get the people in here? We are struggling to fill positions.”

There’s a huge shortage in skilled workers, said Harry Moser, founder of the Reshoring Initiative, which focuses on bringing manufacturing jobs back to the U.S. It’s one reason why companies haven’t returned more positions to the states, he said.

The initiative posts notices on its website about companies expanding production in the U.S. A quick scan found that Whirlpool is adding 50 jobs in Ohio; Moley Magnetics is bringing back more than 40 jobs to New York from Italy, and plastic bottle maker Logoplaste will create 110 jobs in Kansas City, Missouri.

Another looming problem: manufacturing workers are aging and up to 3 million are expected to retire over the next decade, Paul said. Many will need to be replaced.

Related: U.S. has lost 5 million manufacturing jobs since 2000

Manufacturing jobs today, however, require very different skills than those a generation or two ago.

Gone is high-volume, commodity production, such as churning out t-shirts and toys, said James Wall, executive director of National Institute for Metalworking Skills, which sets standards for itsindustry. Those positions have moved overseas and likely aren’t coming back. American manufacturing now involves more precision, technical jobs, such as fabricating airplane parts or artificial knees.

Until the mid-2000s, the majority of manufacturing positions required only a high school degree, Paul said. But now, most need advanced training and skills, such as a proficiency in math and problem solving, as well as technical expertise with certain machines. Many require certificates or additional technical training for specific jobs — such as Computer Numerical Control, in which computers run machine tools such as grinders and lathes.

For instance, workers today need to know right angle trigonometry to program a machine to bore a hole into a metal sheet, Wall said.

Related: Donald Trump and Hillary Clinton are angry about Oreos

Community colleges and private training centers are aiming to fill the gaps. Companies are increasingly working with local colleges to create courses that prepare students for available jobs.

Some high schools are now even developing manufacturing skills programs for the first time in years, Wall said.

Craig Technologies is in touch with area schools, providing internships and tours to students interested in manufacturing jobs. And the local high school teaches some relevant technical courses, such as SolidWorks, a computer-aided design software program.

All these efforts are aimed at building a pipeline of skilled workers.

“The average American has no idea how robust the manufacturing sector has been and is going to be,” Wall said. “We just need to get people the skills to take advantage of it.”

U.S. manufacturers still treading water, Markit shows

Flash PMI barely changed in March at 51.4, growth remains soft

American manufacturers grew slightly faster in March, but many companies say demand is subdued and some are still trying to work off excess inventories, according to a Markit survey.

The Markit Flash PMI rose a tick to 51.4 this month from a 28-month low of 51.3 in February.

Any number above 50 signals expansion, but manufacturers have been barely treading water for months. The PMI average since the U.S. recovery began in mid-2009 is a much stronger 54.1.

“U.S. factories continue to endure their worst spell for three and a half years,” said Chris Williamson, chief economist at Markit. “Headwinds include reduced spending by the struggling energy sector,the strength of the dollar, persistent weak global demand and growing uncertainty caused by the looming presidential election.”

The weak performance of the manufacturing sector is likely to weigh on first-quarter growth.

Source: MarketWatch – Published: Mar 22, 2016 10:45 a.m. ET

Richmond Fed U.S. factory index jumps to highest since 2010

A measure of manufacturing activity in the lower U.S. Atlantic region rose in March to its strongest level in nearly six years, recovering from its weakest level in six months, the Richmond Federal Reserve said on Tuesday.

The Richmond Federal Reserve’s composite factory index rose to +22 points in March from -4 in February.

The latest figure reached its highest level since +26 in April 2010.

The Richmond Fed manufacturing index covers activity in the District of Columbia, Maryland, Virginia, North Carolina, South Carolina and most of West Virginia.

Source: Markets | (Reporting by Richard Leong; Editing by Meredith Mazzilli)

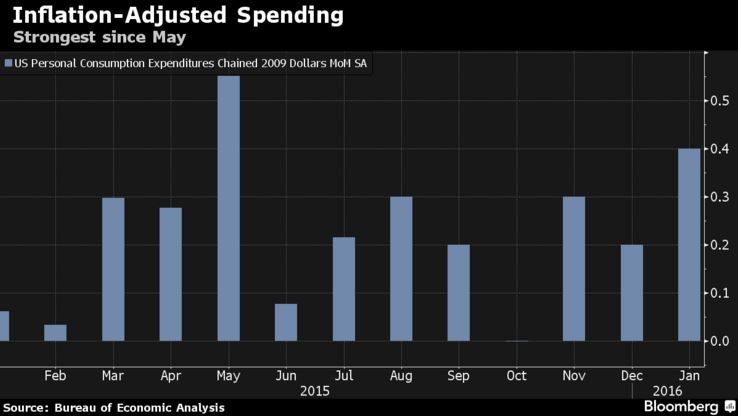

The Fed’s Favorite Indicator Rises by Most in Eight Months

Good news for US economy: Q4 growth revised up, January consumer spending surges

Consumer purchases climbed in January by the most in eight months, fueled by faster earnings growth that’s being accompanied by rising inflation.

The 0.5 percent advance followed a 0.1 percent gain the prior month, a Commerce Department report showed Friday. The January figure exceeded the 0.3 percent median forecast in a Bloomberg survey. Incomes also climbed 0.5 percent, more than projected.

Steady hiring, cheap gasoline, and rising home values are powering Americans’ ability to boost spending, which accounts for almost 70 percent of the economy. The report also showed the Federal Reserve’s preferred measure of inflation rose by the most since October 2014, illustrating the challenge for U.S. central bankers as they consider tighter monetary policy amid feeble global markets.

A separate report from the Commerce Department, also issued Friday, showed gross domestic product expanded at a revised 1 percent annualized rate in the fourth quarter, faster than the previously reported 0.7 percent advance and reflecting a higher value of business inventories.

Projections for January consumer spending ranged from a decline of 0.1 percent to a gain of 0.5 percent, according to the Bloomberg survey. The previous month’s reading was initially reported as unchanged.

Real Spending

The Bloomberg survey median for incomes called for a rise of 0.4 percent, after a previously reported 0.3 percent gain. The January gain was the most since June.

Adjusted for the effect of price changes, spending increased 0.4 percent, the most since May.

Disposable income, or the money left over after taxes, rose 0.4 percent for a second month, after adjusting for inflation. The saving rate held at 5.2 percent. Wages and salaries advanced 0.6 percent following a 0.2 percent increase.

Among other details, household outlays on services rose 0.3 percent after adjusting for inflation. The category, which includes tourism, legal help, health care, and personal care items such as haircuts, is typically difficult for the government to estimate accurately.

Spending Categories

Services spending for last month probably reflected a surge in utility use as colder temperatures returned in January following an unseasonably warm December. A winter storm also blanketed the Mid-Atlantic and Northeast regions with snow late last month.

Spending on durable goods, which includes automobiles, increased 1.1 percent after adjusting for inflation, while outlays for non-durable goods, which include gasoline, rose 0.4 percent.

The Fed’s preferred measure of inflation picked up, the report showed. The price gauge based on the personal consumption expenditures index increased 0.1 percent from the prior month and was up 1.3 percent from a year earlier. Inflation hasn’t reached the Fed’s 2 percent goal since April 2012.

The core price measure, which excludes food and fuel, rose 0.3 percent from the prior month and climbed 1.7 percent from January 2015, which was the most since November 2012.

Fed policy makers are trying to balance concern over market turmoil and slowing overseas economies with signs that U.S. inflation is picking up. They held the target for the benchmark fed funds rate at 0.25-0.5 percent in January after lifting rates at the December meeting for the first time since 2006.

Updated on Bloomberg Business

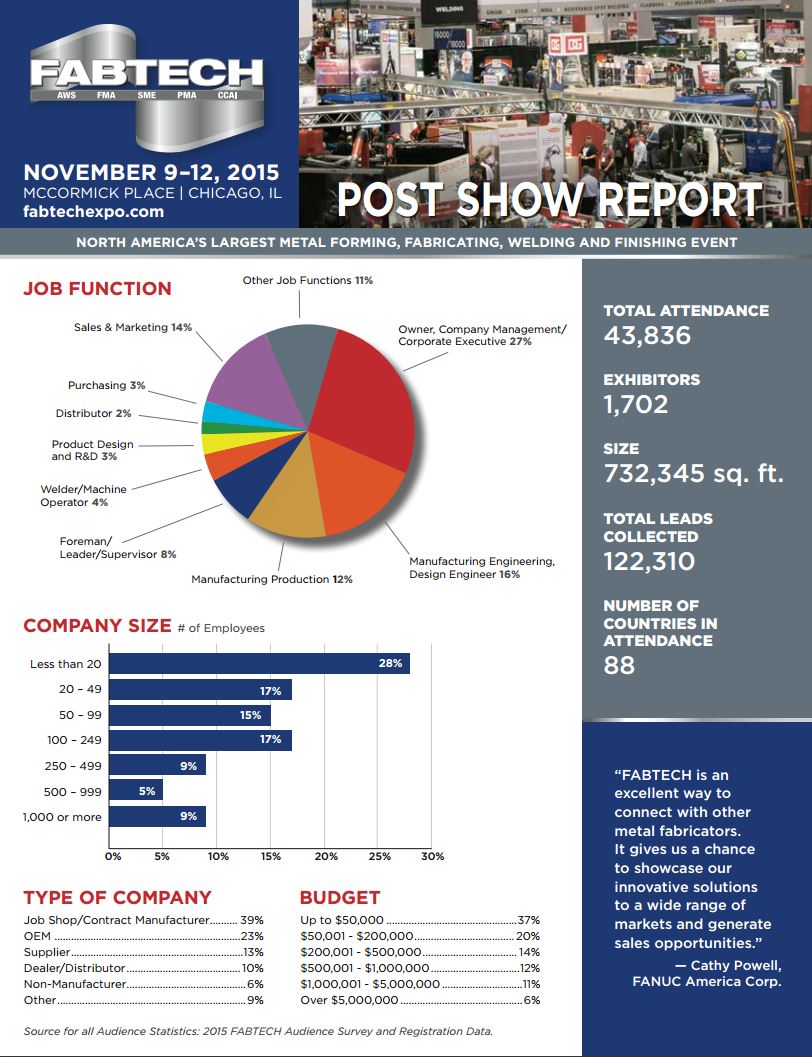

Fabtech 2015 Post-Show Report

FABTECH Post Show Report is out. Click the image for the full report.

FABTECH provides a convenient ‘one stop shop’ venue where you can meet with world-class suppliers, see the latest industry products and developments, and find the tools to improve productivity, increase profits and discover new solutions to all of your metal forming, fabricating, welding and finishing needs.

Click the image for the 2015 Post-Show Report.

See you next time November 16-18, 2016 | Las Vegas Convention Center | Las Vegas, NV USA.

Show Dates & Hours

Wednesday, Nov. 16…… 9:00 AM – 6:00 PM

Thursday, Nov. 17……….9:00 AM – 5:00 PM

Friday, Nov. 18…………..9:00 AM – 4:00 PM

Registration Opens April 2016. Click HERE to be notified when registration opens.

For exhibitors: Las Vegas is gearing up for another successful FABTECH event. The show will be held Wednesday, November 16 – Friday, November 18, 2016 and will encompass three halls at the Las Vegas Convention Center: the North Hall, Central Hall, and Paradise Hall. Space is selling fast! If you haven’t reserved your booth for FABTECH 2016, don’t delay. Visit www.fabtechexpo.com/exhibit or contact a sales representative today to ensure your company is part of this exciting industry event.

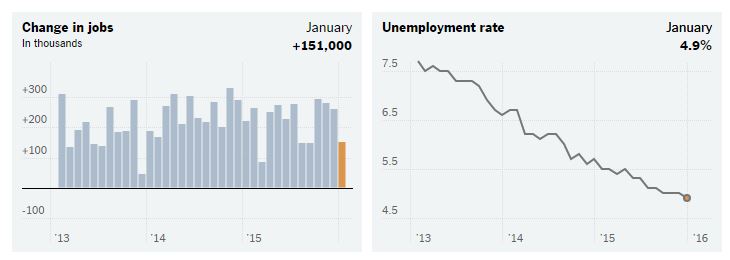

Manufacturers Beat Forecasts By Adding 29,000 Jobs To Payrolls In January.

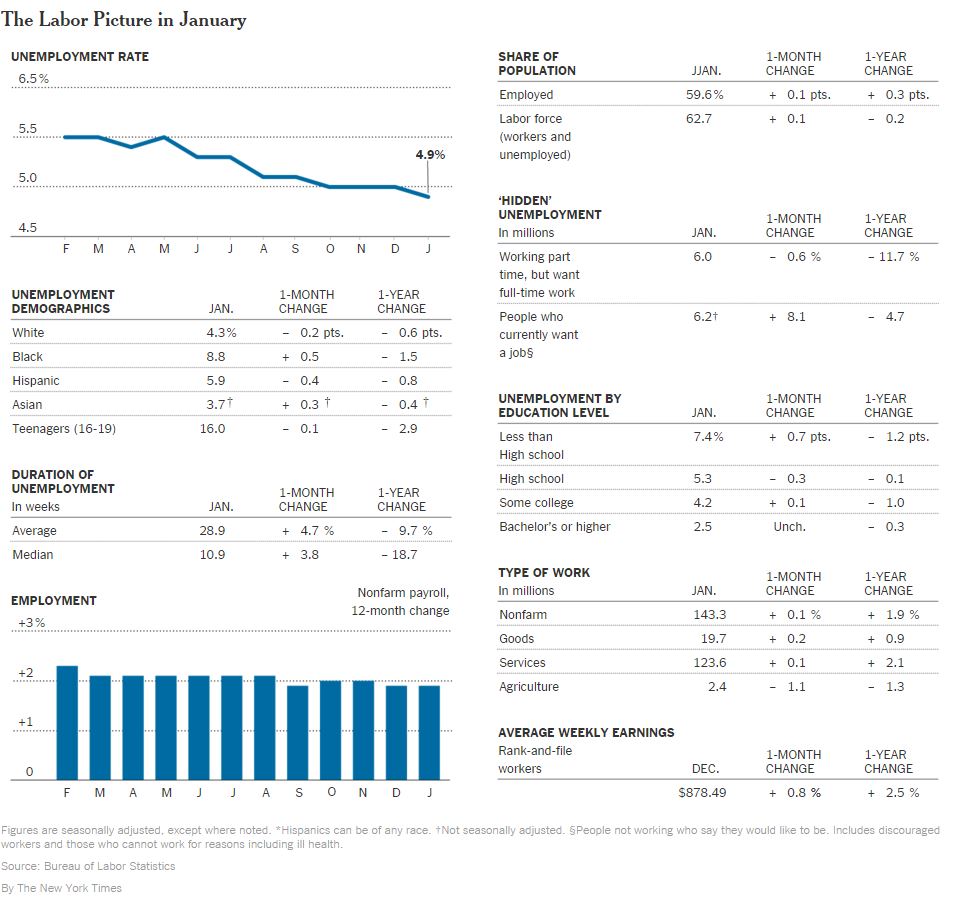

Wages Rise as U.S. Unemployment Rate Falls Below 5%

Is the American worker finally getting a raise?

After years of scant real gains despite steadily falling unemployment and healthy hiring, wages picked up significantly last month, a sign the job market could be tightening enough to force companies to pay more to attract and retain employees.

The half a percentage point increase in average hourly earnings in January was the brightest spot in a generally positive Labor Department report on Friday, which showed job creation slowing from the white-hot pace of late 2015 even as the unemployment rate fell to an eight-year low of 4.9 percent.

The last six months were the best extended period for employee paychecks since the recovery began six-and-a-half years ago.

“That gain in average hourly earnings is significant,” said Diane Swonk, an independent economist in Chicago. Sustained increases are still needed to make up for years of stagnation, she added, “but it’s a move in the right direction, and that’s reassuring.”

Economists also said that the new figures suggested that the American economy was holding up well despite a slowdown in China, growing risks in emerging markets and turmoil in the stock market.

“The financial markets are leery,” said Michael Hanson, a senior economist at Bank of America Merrill Lynch, “but the labor market still looks like it’s continuing to grow.”

President Obama, who expressed frustration that he has not received the credit he feels he deserves for the country’s improving economy, said the jobs numbers were further signs of progress.

“After reaching 10 percent in 2009, the unemployment rate has now fallen to 4.9 percent even as more Americans joined the job market last month,” he told reporters at a White House briefing in Washington. “Americans are working.”

Over all, employers added 151,000 jobs last month, a pace that is strong enough to keep soaking up people looking for work if it continues in the months ahead, but a big step down from December’s revised increase of 262,000.

FABTECH 2015 Celebrated Manufacturing Strength and Innovation in Chicago

CHICAGO, Nov. 16, 2015 – FABTECH 2015, North America’s largest collaboration of technology, equipment and knowledge in the metal forming, fabricating, welding and finishing industries, welcomed more than 1,700 exhibiting companies and a total of 43,836 attendees from over 90 countries last week to Chicago’s McCormick Place.

In the event’s largest and most successful installment yet, attendees were able to learn from and interact with manufacturing’s best by visiting over 730,000 square feet of exhibits, special events and keynote presentations, as well as by participating in educational sessions, an industry night networking event and welding competitions.

“This year’s show was incredible. It’s difficult to fully express our gratitude to all those who made FABTECH a success – the city of Chicago, our loyal exhibitors and the thousands of attendees that not only made the week special, but who continue to drive and move our industries forward,” said Mark Hoper, show co-manager, FABTECH. “Between the variety of events and education programs, to our diverse and expansive show floor, attendees walked away with more knowledge, expertise and industry connections than ever before.”

During the four-day event, attendees found live equipment demonstrations ─ including hundreds of new products and technologies ─ and had one-on-one exchanges with exhibitors and industry leaders. John Quigley from LVD Strippit said, “We have been one of the longest participants in FABTECH and it’s always been a very important venue to show our latest technology to the market place. In North America, it is the most important tradeshow of the year.”

Special event presentation topics at FABTECH 2015 covered additive manufacturing/3D printing, security risks, women in manufacturing, the significance of teamwork within successful organizations and much more.

Speakers and panel participants included representatives from Dell, GE Ventures and other leading companies, as well as NASCAR legend and champion Rusty Wallace. Presidential candidate and former Senator of Pennsylvania Rick Santorum also made an appearance to discuss the importance of American manufacturing.

Additionally, professional welders competed throughout the week at FABTECH for the title of “Best Welder in America” and a $2,500 first place, $1,000 second place and $500 third place prize. Contestants demonstrated their skill by making a single-pass SMAW weld with E7018 on low-carbon steel and were graded on speed and quality. Winners included:

- Aaron Oetken, self-employed welder/fabricator from Mediapolis, Iowa

- Tom Ruge, student, Gateway Technical College from Racine, Wisconsin

- Andrew Miller, welding engineer, Caterpillar Inc. from Dunlap, Illinois

For more information about FABTECH 2015 or FABTECH 2016, taking place Nov. 16-18, 2016, in Las Vegas at the Las Vegas Convention Center, please visit www.fabtechexpo.com.

KELLYC PRESS RELEASES